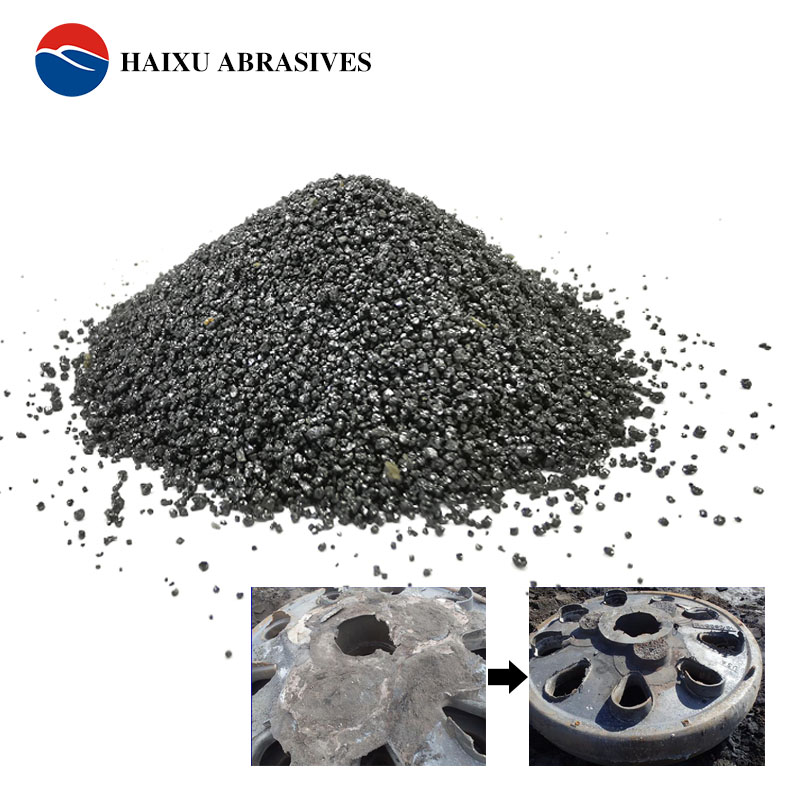

Chromite sand AFS25-30 for lost foam casting

Chromite sand AFS25-30 gets a particle range of 0.4-0.8mm. It always works for lost foam casting process for Casting steel and Casting Iron such as mechanical parts. There are several advantages of casting chromite sand AFS25-30:

1. High refractory performance: Casting Chromite sand has high-temperature resistance and can withstand the pouring of high-temperature molten metal. This makes it suitable for casting high-temperature alloys and large castings.

2. Proper particle size: Chromite sand particles comply with AFS fineness and have high particle roundness, which helps improve the surface smoothness and detail reproduction of the model.

3. Chromite sand is chemically stable. It doesn’t react with steel, Ferro, and the impurity of the casting steel. So it can prevent sand sticking and other defects of casting.

4. High thermal conductivity: Foundry-grade Chromite sand has high thermal conductivity, which means it can absorb and conduct heat faster, accelerating the solidification rate of castings. This is very important for reducing defects and improving product quality.

5. Good durability: Chromite sand has excellent wear and corrosion resistance, which helps to extend the service life of molds, reduce the frequency of mold replacement and maintenance, and improve production efficiency.

6. Low thermal expansion rate. Chromite sand has low liner thermal expansion. The volume doesn’t change after steel casting. So it can help to make precise sizes of castings.