Chromite sand AFS45-55 for casting processes

The main chemical element of chromite sand AFS45-55 is chromium oxide. For the iron & steel castings, the Cr2O2 should be at least 46% and SiO2 content less than 1%. It has high specific gravity and is one of the best high-temperature resistant materials in natural minerals. It has strong thermal conductivity and can be used in various casting processes. Meanwhile, it can eliminate the casting of sand-stick defects substantially.

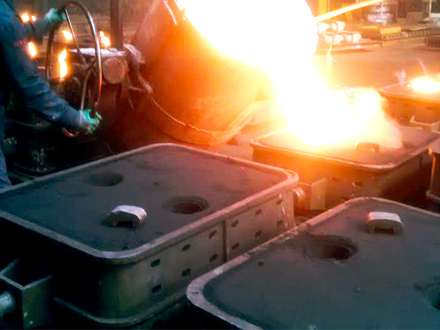

The following are some applicable casting processes:

1. Large and heavy castings with thick walls: Chromite sand works well with green sand and no-bake sand casting processes. It can cool the castings in a predetermined order. That is conducive to improving the internal tightness of the castings and enhancing the strength of the castings.

2. Precision casting: Chromite sand especially AFS45-55 specification can be used for precision casting such as investment casting, shell casting, etc. Those processes can produce high-precision castings such as 304 & 316 stainless steel, and gray ductile iron components.

3. Sand casting: Chromite sand can also be used for sand casting, such as molding sand casting, sodium silicate self-hardening sand casting, etc. It is for the production of various large, medium, and small parts, such as pump bodies, pipelines, valves, etc.

4. Low-pressure casting: Chromite sand can also be used for low-pressure casting, suitable for producing small and medium-sized complex-shaped parts, such as car engine cylinder heads, crankcases, etc.

Overall, chromite sand AFS45-55 works excellently in various casting processes and has a wide range of applications, producing high-precision, high-performance, and high-strength castings.