Chromite sand AFS45-55 AFS50-55 Resin-coated sand Advantages

Chromium ore sand is widely used in no-bake sand casting technology and sand casting, with particle sizes mostly being AFS40-45 (40-70 #), AFS35-40 (20-70 #), etc. For the RCS (resin-coated sand) casting process, finer grains such as Chromite sand AFS45-50/AFS50-55 (50-100 #) or AFS55-60 (70-140 #) are more commonly used as raw sand.

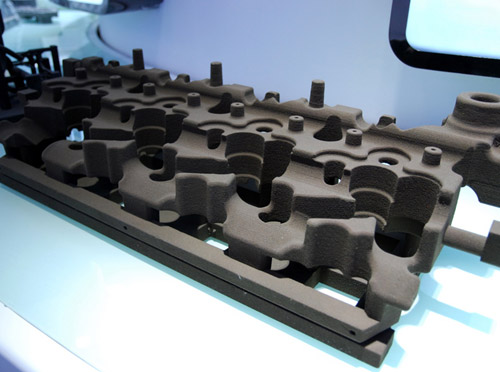

The coated sand casting process is commonly used for complex castings. It has advantages such as high casting accuracy, elimination of sand sticking, and reduction of deformation and porosity defects. The RCS process usually uses natural silica sand as the raw sand and adds a resin-curing agent for shell making. However, the refractory temperature of silica sand is low and its thermodynamic performance is unstable. During pouring, it is easy to react with iron oxide and manganese oxide in the molten steel. The generated chemical substances adhere to the casting as slag chips, causing sand to stick. In addition, for castings made of special materials such as alloy steel and high manganese steel with high pouring temperatures, silica sand cannot meet the requirements. Choosing foundry chromite sand as the raw sand for coated sand can improve the above problems.

The advantages of Chromite sand AFS45-55 AFS50-55 for resin-coated sand are as below:

1. High refractory temperature.

The heat resistance temperature and sintering temperature of chrome ore sand are high. The melting point is 2180 °, and the refractory temperature is higher than 1800 °. It has excellent heat resistance and is suitable for high-temperature applications such as casting shells. Foundry-grade Chrome ore sand does not undergo chemical reactions with molten metal, preventing chemical and physical bonding of castings.

2. Low thermal expansion.

The thermal expansion coefficient of chromite sand is lower than that of silicon sand. At a high temperature of 1000 ° C, the thermal expansion rate of silica sand is 0.15%, while the thermal expansion rate of chromite sand is only 0.06%, which is one-third of that of silica sand. This means that even at high temperatures, chromite sand can maintain its shape and size. This characteristic helps to maintain the precise size and shape of the casting.

3. Strong thermal conductivity.

The thermal conductivity of chromite sand is higher than that of casting sand such as silicon sand and pearl sand, and as the raw sand for coated sand, it also helps to conduct the temperature of molten steel outward.

4. High strength.

The specific gravity of chromite sand is 4.5-4.8g/cm3, while the specific gravity of silica sand is only half that of chromium ore sand. The shell made of coated sand has strong compactness and strength. That makes chromite sand easier to reclaim and recycle.

5. Grain shape and liquidity.

Chromite sand is a type of spherical sand. The sphericity of chromite sand is lower than that of pearl sand or moon sand. However, through a special crushing process, the chromite sand particles will not have sharp corners like olivine sand. This helps to improve the flowability of coated sand.

6. High cleanliness and chemical neutrality.

As a professional foundry-grade chromite sand supplier from China, Haixu processes chromite sand through water washing and demagnetization processes to remove acidic substances from natural chromium ore. Its pH value is 7-9, and its acid consumption value is low. At the same time, the mud content of chromite sand AFS45-55/ AFS50-55 has also been controlled. Therefore, when the resin curing agent comes into contact, there will be no reaction between impurities and the resin. That is conducive to the stable performance of the coated sand.

7. The particle size distribution is appropriate.

The particle size of chromite sand AFS45-55/AFS50-55 is inspected through a 5 ASTM sieve process to ensure that fine and coarse sand meet the requirements of the casting industry. The particle size can vary greatly, which can improve the compactness of coated sand.