The Cr/Fe Ratio of Foundry Chromite sand

The Cr/Fe ratio refers to the ratio of chromium content to Ferro content in chromite ore. The Cr2O3 content of Foundry Chromite sand is more than 46%, the iron (Fe2O3) content is less than 26%, and Cr/Fe ratio is between 1.55-1.60:1.

The Cr/Fe ratio has a significant impact on the performance of chromite sand. On the one hand, chromite sand with a low Cr/Fe ratio has a lower refractory temperature. That affects its total energy as a refractory material for foundry. Especially for its slag resistance and anti sticking properties as casting sand. On the other hand, if Cr/Fe ratio is too low, it will result in insufficient strength of the chromite sand. When mechanically recycling casting sand, insufficient strength means it is prone to breakage. It affects the recycling rate of chrome ore sand casting sand.

In the chrome ore in South Africa, chromite located within 400 meters below the surface belongs to the UG layer, with a chromium content of 40-43% and Cr/Fe ratio of 1.26-1.4:1. The deeper MG layer is the middle layer of chromite, with a chromium oxide content of 44-46% and Cr/Fe ratio of 1.35-1.5:1. Further down 800 meters is the LG layer of chromite ore. The Cr2O3 purity of LG Chromite is 46-47%. And Cr/Fe ratio of LG chromite ore is 1.56-1.60:1. As a professional Foundry Chromite sand supplier, Haixu Abrasives adopt LG ore layer as the raw ore from South Africa, ensuring the fire resistance and strength of chromite sand for foundry.

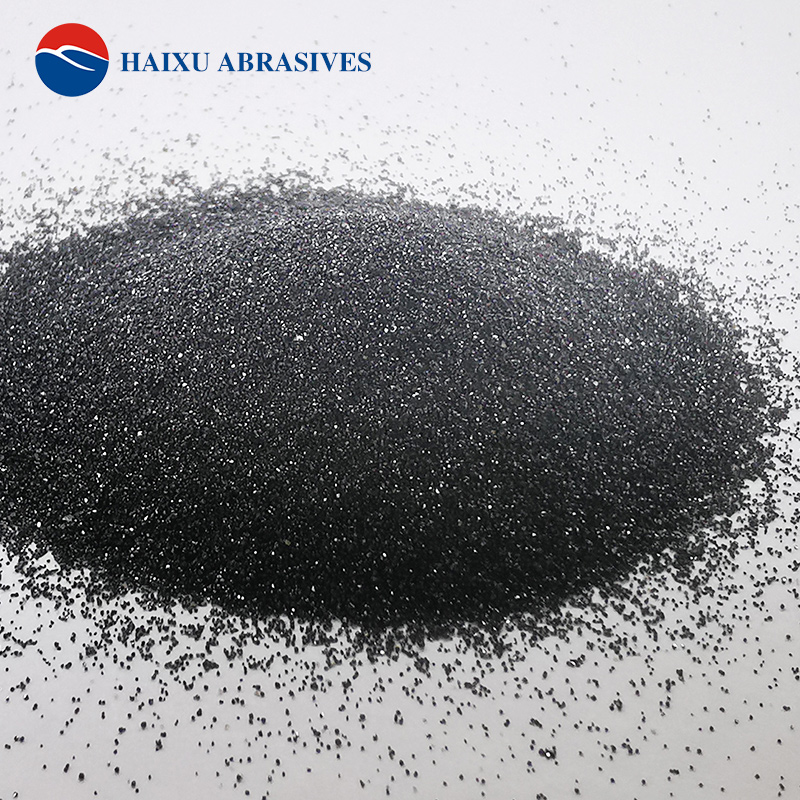

Available AFS size from our Chromite sand: AFS 25/30, AFS30/35, AFS35/40, AFS40-50, AFS40-45, AFS45-50, AFS45-55, AFS50-55, AFS55-60,etc.