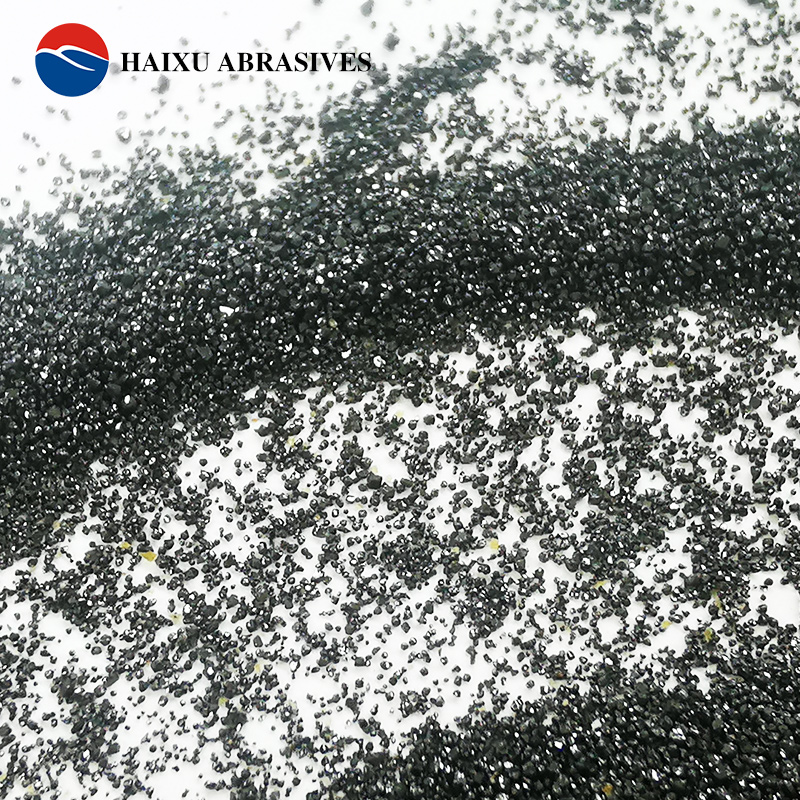

Foundry chromite sand Advantage and Usage

Foundry chromite sand has become a commonly used foundry sand in the fields of machinery and equipment, railway parts, etc. due to its excellent refractory temperature, resistance to steel sand erosion, anti-sticking sand, strong thermal conductivity, and high cost performance. The chromium content of chromite sand for foundry is not less than 46%, and the silicon content is not more than 1%.

1. Applicable steel types

Foundry chromite sand is mainly used as facing sand for high-manganese steel, alloy steel and other castings with high pouring temperatures. Typical applications include:

- High manganese steel (such as ZGMn13): strong resistance to metal penetration and reduced sticking sand.

- Alloy steel: such as high-chromium alloy steel (40Cr), nickel-based alloy, cobalt-based alloy (need to withstand extremely high pouring temperatures).

- Carbon steel and structural steel: No. 45 carbon steel, A3 steel, etc.

- Gray cast iron and ductile iron: HT150, etc.

- Stainless steel: such as 304, 316, etc. (chromium ore can resist chromium oxide erosion).

2. The advantages of chromite sand for casting

- High refractoriness (≥1850℃): far exceeding silica sand (about 1700℃), suitable for high-temperature molten steel.

- Low thermal expansion coefficient: reduce surface cracks and deformation of castings.

- Anti-metal penetration: prevent molten steel from penetrating into sand molds and reduce sand sticking defects.

- High thermal conductivity: fast heat conduction and heat dissipation, which is conducive to the sequential solidification of large castings.

- Alkaline properties: compatible with alkaline slag such as high manganese steel, reducing chemical reactions.

3. Typical casting process applications

- Face sand layer: the surface of the mold cavity that directly contacts the molten steel (usually 20-50mm thick), and the back sand can still use silica sand to reduce costs.

- Local key parts: such as areas around the gate, riser or thick wall, which require high refractory protection.

- Lost foam casting: as a coating aggregate to improve the surface finish of the casting.

4. Comparison with other surface sand materials

| Index | Chromite sand | Silica sand | Zircon sand | Forsterite sand |

| Refractoriness(℃) | ≥1850 | ≈1700 | ≥2000 | ≈1700 |

| Thermal expansion rate | Very Low | High | Low | Medium |

| Metal penetration resistance | Excellent | Low | Superior | Good |

| Cost | Medium | Low | High | Medium |

5. Fineness of foundry chromite sand:

Mesh size: 20-70 mesh, 30-70 mesh, 40-70 mesh, 50-100 mesh, 70-140 mesh, etc.

AFS specifications: AFS35-40, AFS40-45, AFS35-45, AFS45-50, AFS45-55, AFS50-55, AFS55-65, etc.

In summary, foundry chromite sand is a cost-effective choice for high manganese steel, alloy steel, stainless steel casting, cast steel, and ductile iron casting. The price is much lower than zircon sand, and the performance is better than silica sand and olivine sand.