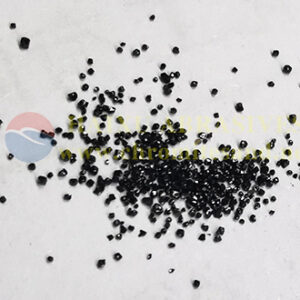

Refractory Chromite sand AFS35-40

Product Introduction of Refractory Chromite Sand AFS35-40

Refractory Chromite sand AFS35-40 is a type of chilled material, and natural chromium ore (chromite ore) with a 46% content is the main material for producing chromium-based drainage sand. In continuous casting production, the automatic pouring rate of molten steel, also known as the pouring speed, is very important. The opening rate refers to the volume rate at which molten metal steel enters the mold. If the speed is too slow, the metal will cool and solidify before filling the mold cavity. Therefore, improving the automatic pouring rate of continuous casting is particularly important. The quality of the drainage sand has a direct impact on the pouring rate.

Typical chemical analysis of Refractory Chromite Sand AFS35-40

| CHEMICAL COMPOSITION | |

| Cr2O3 | 46.5% |

| SiO2 | 0.4% |

| FeO | 26.3% |

| CaO | 0.2% |

| MgO | 9.8% |

| AL2O3 | 15.2% |

| P | 0.001% |

| S | 0.001% |

| Moisture (105°C) | 0.01% |

| Cr/Fe | 1.55:1 |

Typical physical properties of Refractory Chromite Sand AFS35-40

| Hardness: | Mohs:5.5-6 |

| Melting Point: | Sublimes at 2180 °C |

| Sintering point: | >1800°C |

| Specific Gravity: | 4.0-4.8 g/cm3 |

| Bulk density(LPD): | 2.5-3 g/cm3 |

| Turbidity (JTU) | 110 |

| Color: | Black |

| PH Value | 7.3 |

| Percentage of free acid present in the sand: | 0% |

| The amount of the acid: | ≤2ML |

| Percentage of soil: | ≤0.1 |

| Percentage of Moisture: | ≤0.1 |

Characteristics of Refractory Chromite Sand AFS35-40

The drainage sand is located in the gap between the bottom of the ladle and the water inlet and filled to the bottom of the ladle. In the early stage of molten steel smelting, the drainage sand above the nozzle contacts the molten steel and quickly sinters to form a sintered layer that organizes the infiltration of molten steel. The drainage sand below the water inlet needs to withstand the static pressure of the molten steel without being damaged. When pouring, the non-sintered part of the drainage sand falls due to its own weight, causing the sintering layer to lose support and break, causing molten steel to flow out and achieve pouring. If quartz sand is used as the main raw material for siliceous drainage sand, the pouring rate will significantly decrease after the pouring time exceeds 1 hour. This is because the sintered layer of siliceous drainage sand gradually thickens and is difficult to break, making it difficult for molten steel to break through and flow out normally.

However, with the widespread application of external refining and continuous casting processes in steel production enterprises, the pouring time will be extended to more than 2 hours, and siliceous drainage sand cannot meet the requirements of maintaining the pouring rate. Chromium-based drainage sand is gradually replacing silicon-based drainage sand.

The main component of chromium drainage sand is natural chromium ore sand with a Cr2O3 content higher than 46%. It can still maintain the pouring rate above 95% after the molten steel has been left standing for more than 100 minutes.

- Heated Volume Stability

- High thermal conductivity

- Strong alkali resistance

- Solid phase sintering, non-sticking sand

Applications of Refractory Chromite Sand AFS35-40

In steel production, Chromite Sand is used as well as a filler for protection of the sliding gate in large steel holding ladles.

In the ladle well filler, when the added amount of chromite is greater than 60%, the chromite is continuously distributed, and this distribution helps to form a continuous sintered layer. At high temperatures, FeO in the chromite reacts to desolvate and form secondary spinel, which causes the volume of the sintered layer to change and crack. In this way, when the sliding plate is opened, the unsintered drainage sand under the nozzle will flow out quickly, and the cracks in the sintered layer will rapidly expand, The sintered layer is completely destroyed under the action of the static pressure of molten steel so that the purpose of automatic pouring can be achieved. Chromium drainage sand is used by most large steel mills, accounting for about 30% of the entire drainage sand for ladles, especially for refined ladles.

Refractory Chromite Sand AFS35-40 Production:

Refractory Chromite Sand AFS35-40 Package:

FAQ:

Q: Where are you located?

A: Our factory is located in a tariff-free Zone at Lianyungang port. So it will be convenient to export.

Q: What is your main market?

A: Our main market is local China and Asia-Pacific regions.

Q: What is the difference between your chromite sand and Original South Africa Chromite sand?

A: In our factory, we take production processes on original South Africa such as washing, magnetic removing, and sieving. So it is cleaner with fewer impurities, less magnetic content. The cleanness of chromite from us is just proper for the foundry industry. In the meantime, we will get a precise AFS size and make customized particle size distribution to the requirement.

Q: Do you have a limit of MOQ?

A: No. We don’t have a limit on MOQ, but for small quantities, the transportation cost would be high.

Q: Can you provide free samples?

A: Yes, free samples within 25 kgs are available. You only have to bear the express cost.

Q: What is the delivery time for one container?

A: Generally the lead time of FCL is 7-10 days. A bigger quantity will get a longer delivery time.

Q: What is the HS code of Chromite sand?

A: The chromite sand HS code is 2610000000.

Q: Do you get MSDS of chromite sand?

A: Yes. You can download it from our website or get it from our sales team.