Casting chromite sand AFS45-50 AFS40-45 delivery

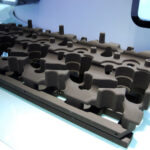

Casting chromite sand AFS45-50 AFS40-45 are mostly used for steel casting and iron casting. The consumption quantity is large. Recently we delivered 1000 tons for the customer in North Asia.

Home > News

Casting chromite sand AFS45-50 AFS40-45 are mostly used for steel casting and iron casting. The consumption quantity is large. Recently we delivered 1000 tons for the customer in North Asia.

Chromite sand AFS 40-45 is a quick chilling material with high refractory temperature and excellent thermal conductivity. Therefore, in the casting of cast iron, it is necessary to prevent cold iron from being replenished outside the casting to prevent expansion and deformation of the cast iron after pouring.

Chromite sand AFS40-45(40-70mesh)is a commonly used foundry sand for the resin No-bake process. Resin no-bake sand is generally a casting molding method for foundry. In this procsss, the furan resin is added to the original sand for mixing. And then the molding sand can self-harden without heating or adding air. This casting process does not require high equipment requirements, has high casting accuracy, and is widely used. However, the resin No-bake process has high requirements for the original sand. Especially for the recycling and reuse of casting sand. It requires high requirements for the hardness, strength, particle size, acid consumption value, etc. of the original sand.

Chromite ore sand AFS 55-60 is a high-quality casting sand for shell molding. This sand generally refers to the high thermal strength, long heat resistance time, and small deformation at high temperatures. It can take a tough task that silica sand can’t do.

Chromium ore sand is widely used in no-bake sand casting technology and sand casting, with particle sizes mostly being AFS40-45 (40-70 #), AFS35-40 (20-70 #), etc. For the RCS (resin-coated sand) casting process, finer grains such as Chromite sand AFS45-50/AFS50-55 (50-100 #) or AFS55-60 (70-140 #) are more commonly used as raw sand.

Dry Chromite sand is usually used for large, heavy, and structurally complex casting surface dry sand. Dry sand in casting needs to have high sand mold strength, fire resistance temperature, and resistance to molten steel erosion. Besides the sintering temperature and thermal conductivity, the moisture of chromite sand is an important technical index as well.