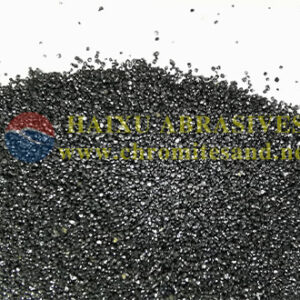

Chromite Sand for Ladle Drainage Sand Features:

1. Heated Volume Stability

2. High thermal conductivity

3. Strong alkali resistance

4. Solid-phase sintering, non-sticking sand

| CHEMICAL COMPOSITION | |

| Cr2O3 | ≥46.0% |

| SiO2 | ≤1.0% |

| FeO | ≤26.5% |

| CaO | ≤0.3% |

| MgO | ≤10% |

| AL2O3 | ≤15.5% |

| P | ≤0.003% |

| S | ≤0.003% |

| Cr/Fe | 1.55:1 |

| TYPICAL PHYSICAL PROPERTIES | |

| Hardness: | Mohs:5.5-6 |

| Melting Point: | Sublimes at 2180 ℃ |

| Sintering point: | >1800℃ |

| Specific Gravity: | 4.0-4.8 g/cm3 |

| Bulk density(LPD): | 2.5-3 g/cm3 |

| Colour: | Black |

| PH | 7-9 |

| Percentage of free acid present in the sand | 0% |

| The amount of acid | ≤2ML |

| Percentage of soil | ≤0.1 |

| Percentage of Moisture | ≤0.1 |

Sizes for Chromite Sand for Ladle Drainage Sand

AFS 30-35,AFS35-40

Application of Chromite Sand for Ladle Drainage Sand:

Chromite Sand in the steel industry

In steel production, Chromite Sand has used filler to protect the sliding gate in large steel holding ladles.

In the chromium drainage sand, when the added amount of chromite is greater than 60%, the chromite is continuously distributed, and this distribution helps to form a continuous sintered layer. FeO in the chromite reacts to desolvate and form secondary spinel at high temperature, which causes the volume of the sintered layer to change and cracks. In this way, when the sliding plate is opened, the unsintered drainage sand under the nozzle will flow out quickly, and the cracks in the sintered layer will rapidly expand, The sintered layer is destroyed under the action of the static pressure of molten steel so that the purpose of automatic pouring can be achieved. Most large steel mills use chromium drainage sand, accounting for about 30% of the entire drainage sand for ladle, especially for the refined ladle.

Jackson (verified owner) –

Good quality.

Samuel (verified owner) –

Very fast delivery.

Max (verified owner) –

Very fast delivery.

Owen (verified owner) –

The product is firmly packed.

Samuel (verified owner) –

Good service.

Phoenix (verified owner) –

Good service.

David (verified owner) –

Good service.

Matthew (verified owner) –

Very well worth the money.

Samuel (verified owner) –

Very well worth the money.

Ryker (verified owner) –

Good service.

John (verified owner) –

Good service.

Phoenix (verified owner) –

Very well worth the money.

Angel (verified owner) –

Very fast delivery.

Ryker (verified owner) –

Very well worth the money.

Paul (verified owner) –

Very well worth the money.