Why choose chromium ore sand with low turbidity?

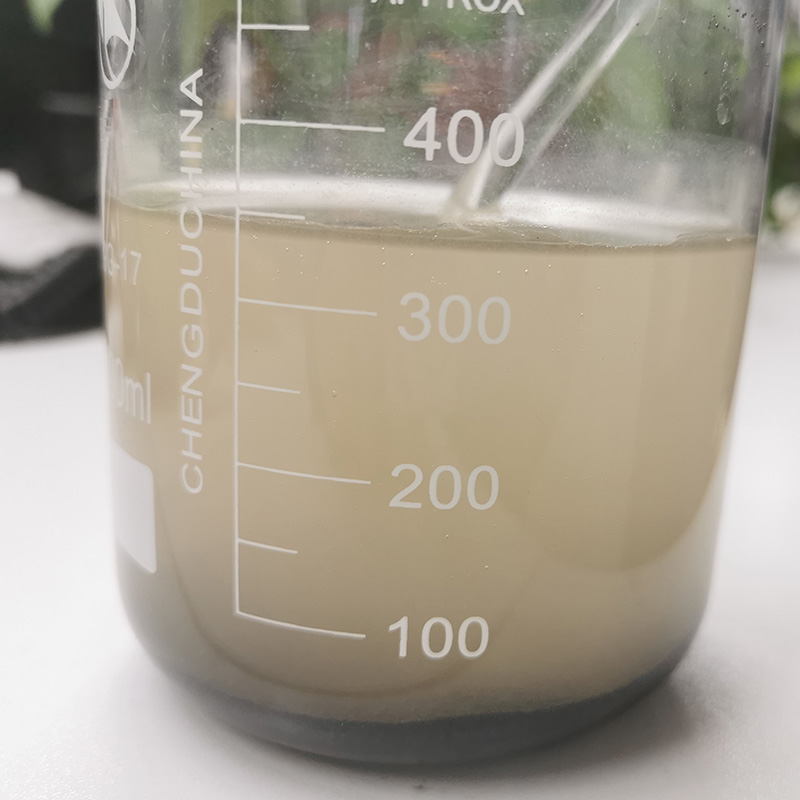

The turbidity of chromium ore sand is an important indicator for determining its cleanliness, mud content, and dust. It directly affects the performance of various indicators of chromium ore sand during the casting process.

The American Foundry Society (AFS) stipulates that the turbidity of foundry-grade chromium ore sand shall not exceed 0.2%. Due to the extraction of chromium ore sand from natural chromium ore, half of the impurities after crushing will be released from the ore, including sediment, siliceous yellow skin, etc. These impurities can affect the refractory temperature and strength of chromium ore sand. Especially in the casting of sodium silicate no-bake sand and resin sand, if the dust content of chromium ore sand is high, it will increase the amount of binder added and also increase the gas generation rate. As a result, the usage time of chromium ore sand foundry sand is reduced, and the strength of the surface sand is reduced.

How to solve the problem of high turbidity of chromium ore sand? Improvements can be made in the following areas:

- For the problem of high mud content, a pre-washing method is adopted to remove sediment and dust.

- To address the issue of moisture content, the method of washing with water and drying is used to remove residual moisture.

- For the problem of silicon content that can easily cause casting sand to stick, a multi-step magnetic separation method is adopted to remove silicon iron and magnetic substances.