Foundry chromite sand AFS 45-55 key technical index

Foundry-grade chromite sand AFS 45-55 – the work-horse for heavy-section steel and manganese-steel castings – is bought on a very short list of numbers.

The “key technical index” that meet GOST 23409.24-78 and SFSA 16 T-67 standard given below. If any item drifts outside these bands the sand is either rejected or priced down.

| Index | Requirement |

| SiO₂ | ≤ 1.0 % |

| Cr₂O₃ | ≥ 46 % |

| FeO + Fe₂O₃ (total Fe as FeO) | 26 – 30 % |

| Al₂O₃ | ≤ 12 % |

| MgO | ≤ 8 % |

| CaO | ≤ 0.5 % |

| P | ≤ 0.003 % |

| S | ≤ 0.002 % |

| Cr/Fe | ≥ 1.55:1 |

| Loss on ignition (1 000 °C) | ≤ 0.2 % |

| Acid demand value (ADV) | ≤ 5 ml |

| PH | 7-9 |

| Moisture | ≤ 0.1 % |

| Bulk density | 2.6 – 2.8 g cm⁻³ |

| Specific gravity | 4.4 – 4.6 g cm⁻³ |

| Thermal linear expansion (20 – 1 000 °C) | ≤ 0.4 % |

| Thermal conductivity | 0.63 W/M·K |

| Melting point | ≥ 1 800 °C |

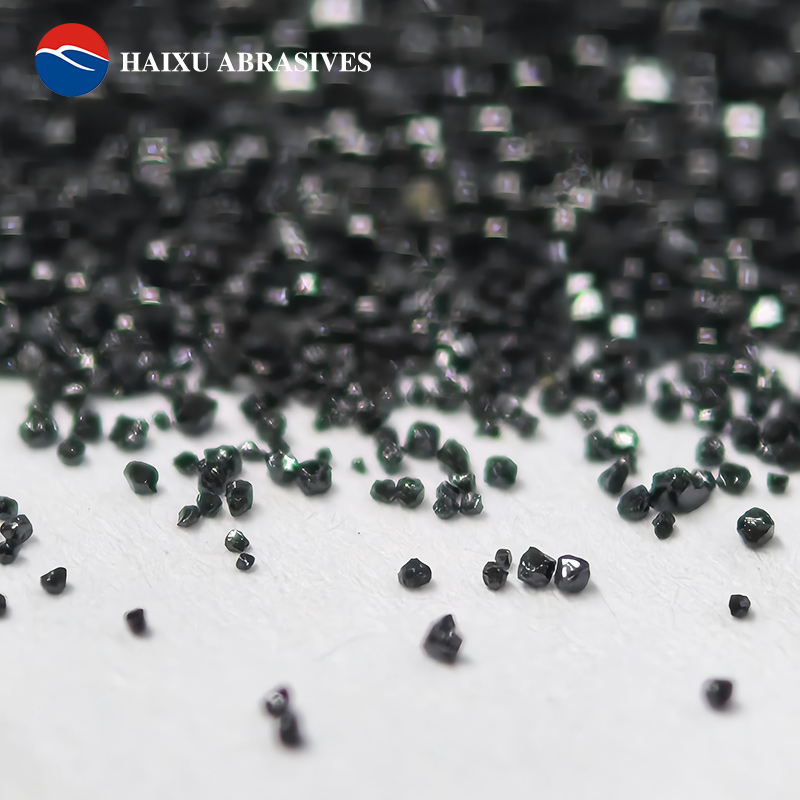

| Grain shape | sub-angular to angular |

| Colour | glossy black |

| Magnetic particles | ≤ 0.1 % |

| NTU | ≤ 300 |

| Grain Fineness number (GFN) | AFS 45-55(AFS45/55) |

| Average grain size | 0.26-0.32mm |

Notes

1. The Cr₂O₃ ≥ 46 % gate is the single most important discriminator; below 45 % the refractoriness and chilling power fall off quickly.

2. SiO₂ > 1 % is rejected outright because free silica accelerates burn-on and fayalitic penetration in manganese-steel casts.

3. ADV ≤ 3 ml guarantees that the sand will not rob acid from phenolic-urethane or furan binders, keeping strip times and strengths on target.

4. AFS 45/55 corresponds to a weight median diameter of ≈ 260–320 µm – coarse enough for high permeability in 100 kg–50 t moulds, fine enough to give a 3–4 µm Ra surface on the casting.

Хромит песок AFS45-55,Песок хромитовый AFS45-55, Песок хромита AFS45/55, Хромитовый песок, Хромитовый песок AFS45-55, Хромовая руда, песок хромитовый AFS 45/55,Песок хромитовый AFS 45-55